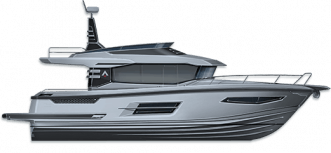

We launched a full cycle of production of boats of the Arctic brand. Construction is carried out strictly according to the standards of Norwegian shipbuilders; the difference from European production is the presence of its own composite materials laboratory, where selected samples are tested and verified before they are used in construction.

The hulls of our boats are of sandwich construction, made using advanced vacuum infusion technology. We did not use balsa, unlike our Finnish colleagues, only special cellular mats in the side sections. The underwater part is completely monolithic, reinforced with a developed system of stringers using carbon fiber (carbon). The profile stringer system is filled with foam and molded to the hull as one piece. High strength and rigidity of the body can withstand any load.

The outer side of the roof is made of 50% carbon fiber, and the radar arch-wing is made entirely of carbon. This gave us amazing stability and directional stability in heavy seas, as the center of gravity and overall weight of the boat was reduced.